Send us a product inquiry today!

DRY SYSTEMS PRODUCT INFORMATION FOR

Pulse Valves

Working Principles

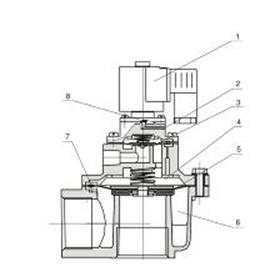

The electromagnetic pulse valve is composed of electromagnetic pilot operator, diaphragm and valve body. Due to difference of pressure acting on two sides of the diaphragm, the diaphragm is pressed closely against the outlet of valve to keep the valve stays in “closed” position.

When energized by an electric signal from the controller, the electromagnetic armature will move to open the discharge opening of back cavity. The compressed air in back cavity bursts out to relief pressure and pressurized air in front cavity pushes up the diaphragm to open the main outlet of valve, then the electromagnetic pulse valve opens and starts to blow.

When the signal disappears and the spring works immediately to send the pilot operator back to its original position and close the discharging opening. The diaphragm will close the passage by the effect of the pressure in the front cavity and the spring. The pulse valve stops blowing.

The orifice in the diaphragm damps the airflow when the armature is lifting up for releasing the pressure. When the discharge hole closed, the pressure gas will fill into the front cavity to close the passage by the diaphragm. The pulse valve stops blowing.

Application

Electromagnetic pulse valve, also called diaphragm valve acts as a “switch” for compressed air in the dust clean blowing system for pulse bag filters. It is controlled by the electric signals from the pulse-jet control device. This system cleans the filter bags cluster by cluster with high-pressure blowing to keep the pressure resistance of the baghouse within a pre-set range, and thus ensure the processing capability and the dust-collecting efficiency of the baghouse.

1. electromagnetic coil, 2. discharge opening, 3. small diaphragm, 4. back cavity of diaphragm, 5. big diaphragm, 6. front cavity of diaphragm, 7. orifice, 8. electromagnetic armature

DRY SYSTEMS TECHNICAL SPECIFICATION FOR

Pulse Valves

Working Pressure: 4-6 bar

Working medium: clean air

Power supply: DC24V (AC 220V/50Hz to 240V/60Hz)

Class of protection: IP65

Working environment:

Normal-temperature diaphragm: -20°C to 80°C

High-temperature diaphragm: 55°C to 180°C

The relative humidity of air is no more than 85%

DRY SYSTEMS TECHNICAL SPECIFICATION FOR

Low Pressure Pulse Valves

Working Pressure: 0.5-1 bar

Working medium: clean air

Power supply: DC24V (AC 220V/50Hz to 240V/60Hz)

Class of protection: IP65

Working environment:

Temperature: -40°C to 130°C

The relative humidity of air is no more than 85%