WET SYSTEMS PRODUCT INFORMATION FOR

Vortex Scrubbers

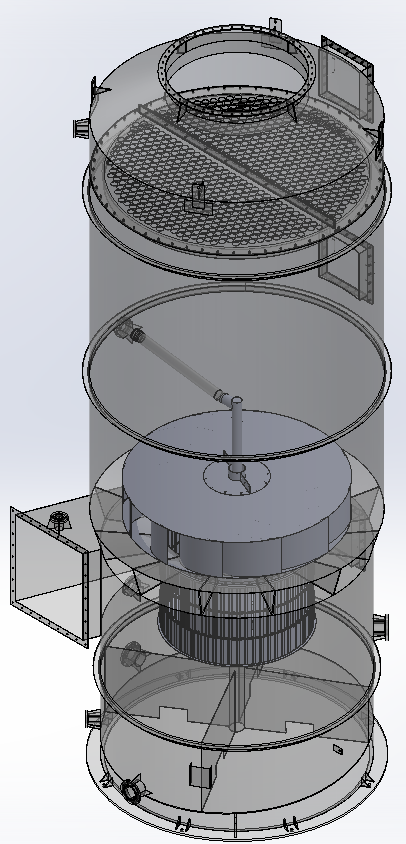

The Watson Enhanced Vortex (WEV) Scrubber is a pressure drop-driven wet scrubber which uses a unique principle to achieve high scrubbing efficiency of particulates and acid gases. It uses energy more efficiently than conventional scrubbers, with the majority of applications requiring less than 10" wg pressure drop. It is adjustable to suit changes in gas flow or scrubbing efficiency.

Advantages:

Scrub a wide range of particle sizes, fixed or adjustable pressure drop

No nozzle needed for liquid atomization

No moving parts

Multiple treatments in the same housing

Retrofits easily into existing ductwork

Better performance characteristics than venturi scrubber

Material of Construction:

Metals: 304, 316 stainless steel, carbon steel

Plastic: FRP and thermoplastic lined FRP

Available in any fabricating material

Performance Calculations:

To calculate the scrubber operating data to meet the emission specification, we require the process data listed int the scrubber inquiry sheet (available upon request). It is particularly important to define the pollutants and, in the case of particulates, to provide the particulate size distribution (PSD) with at least 5 data points. This is necessary for checking he number of particular size species present and the consistency of the data. For particulate scrubbers, the pressure drop is determined by a pressure drop computation program (using the PSD).

Typical Applications:

Particulate scrubbing (in dryer exhausts, food products, biomass boiler, mineral processing)

Particulate + absorption (in coal boiler, pulp mill smelt tank)

Absorption (in bleachery)

We supply:

WEV Scrubber complete with all necessary accessories, coupled with system fan and stacks for rain-out types.

Principle of Operation:

The scrubbing liquid is introduced into the droplet generator (Atomizer) and is sheared into droplets by the high velocity spin action induced in the gas passing through a stationary vane assembly built into a cyclonic housing. Some of the droplets flush the walls of the cyclonic housing, while the balance form a dynamics rotating droplet cloud through which all the gas and pollutants must pass. The inlet gas is thus treated to 3 types of contacting in the same housing:

Gas quenching (i.e., it is cooled to its adiabatic saturation temperature)

Coarse particulates are removed by wet cyclonic action

Fine particulates and acid gases are removed in the rotating droplet cloud

The spent scrub liquid drains to the bottom of the scrubber. The balance, as entrained mist, is separated in the high efficiency mist eliminator above.