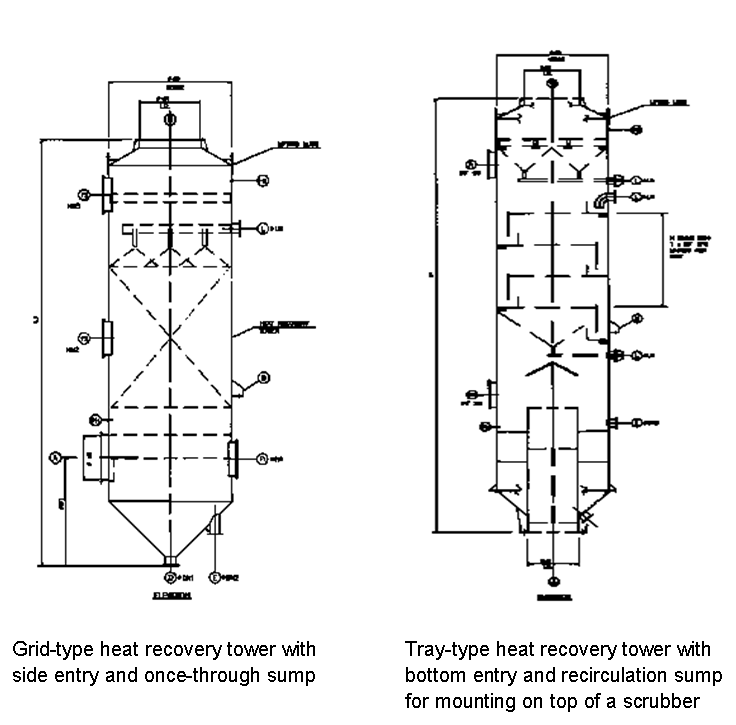

WET SYSTEMS PRODUCT INFORMATION FOR

Heat Recovery Towers

Our heat recovery towers performs the following functions:

It quenches the gas (if it is not already water saturated) It recovers the heat from the inlet gas It condenses out excess moisture The gas discharges to the atmosphere at a much lower temperature than before As a result of the condensation of moisture in the tower, additional particulate is "scrubbed" from the gas

These are the most thermally efficient and have the lowest capital cost. Tray tower shortcomings: high pressure drop (~3" WG per tray) and more susceptible to fouling with solids.

These are less efficient and more expensive than tray towers. Their advantages over trays: much lower pressure drop and much less susceptible to fouling.

These are less efficient and more expensive than tray towers. Their advantages are: low pressure drop and negligible likelihood of fouling.

Along with the tray tower, these are the most thermally efficient. Depending on whether, plastic or metal packing can be used, they can also be the cheapest. Feature of this type: low pressure drop and most susceptible suspectable to fouling with solids.

Most product dryer exhausts have to pass through some type of air pollution control equipment to remove solid particulate. The residual particulate content governs the selection of the type of heat recovery device. Some examples are: pulp/paper machine dryer (spray), food product drying (low particulate - tray; high particulate - grid), mineral product drying (grid tower), boiler off gas, scrubbed, low particulate (packed).

Heat recovery towers complete with all internals and flanged nozzles. Installation and peripheral equipment is by others.